Screeds: Essential Flooring Products for Durable and Level Surfaces

Screeds are a vital category of flooring products used to create smooth, level, and durable surfaces in both residential and commercial construction projects. They are applied as a top layer over concrete subfloors to provide a strong and even base for the final floor covering, such as tiles, vinyl, wood, or carpet.

They are also widely used in new builds, renovations, and industrial settings where a high-performance, long-lasting flooring solution is required.

Types of Screeds

Screeds come in various formulations to suit different applications and project requirements:

- Traditional Sand and Cement – These are mixed on-site and applied manually, offering a cost-effective solution for basic levelling and load-bearing applications.

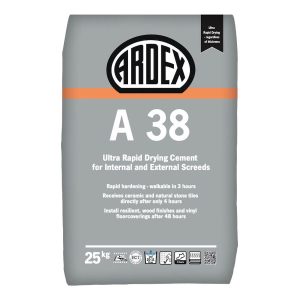

- Fast-Drying – Designed for projects with tight deadlines, allowing for quicker installation of final floor coverings.

- Self-Levelling – Flowable formulations that spread easily to create a perfectly level surface with minimal manual finishing.

- Fibre-Reinforced – Contain fibres for enhanced strength, reducing the risk of cracking and shrinkage.

- Polymer-Modified – Include added polymers to improve adhesion, flexibility, and durability, making them suitable for challenging environments.

- Anhydrite – Based on calcium sulphate rather than cement, offering excellent self-levelling properties and reduced shrinkage.

Key Benefits of Screeds

- Enhanced Durability – Screeds improve the lifespan and performance of flooring systems by providing a stable base that resists wear and impact.

- Improved Floor Levelling – They ensure an even, smooth finish, which is essential for installing tiles, wood flooring, and other floor coverings.

- Fast Installation – With advanced formulations, screeds can set quickly, reducing project timescales.

- Moisture Resistance – Certain screeds provide additional protection against dampness, making them ideal for wet areas.

- Underfloor Heating Compatibility – Many screeds are specifically designed to work efficiently with underfloor heating systems, ensuring even heat distribution.

Applications of Screeds

Screeds are commonly used in a variety of environments, including:

- Residential properties – Providing smooth and level floors in homes.

- Commercial buildings – Ensuring durable flooring solutions for offices, shops, and public spaces.

- Industrial facilities – Creating hard-wearing surfaces that can withstand heavy loads.

- Healthcare and education sectors – Offering hygienic, low-maintenance flooring solutions.

Choosing the Right Screed for Your Project

When selecting a screed, consider factors such as drying time, load-bearing requirements, compatibility with underfloor heating, and environmental conditions.

Whether for new construction or renovation projects, choosing the right screed ensures long-term durability and performance.

Contact BaseTec - Complete Systems. Reliably Delivered.

If you require assistance with screeds or need advice on which product is best suited for your requirements, contact our friendly teams in Kent - 01732 906 826 - or Leeds - 0113 521 6789.

Return to our full range of

Flooring Products.