Premium pure epoxy resin approved for use in cracked and non-cracked concrete.

Features and benefits:

- Approved for use with threaded rods for use in cracked and non-cracked concrete (EAD 330499-01-0601), working life up to 100 years df

- The strongest resin in the epoxy resin class

- Suitable for use in dry and wet substrates including flooded holes (use category I1 & I2) Seismic category C1, C2

- Installation direction D3 (downward and horizontal and upwards installation)

- Minimal shrinkage provides option of use in diamond-drilled holes and oversized holes

- Very high chemical resistance – suitable for applications exposed to influence of various agents (industrial or marine environment)

- Extended working time ensures easy installation of metal components (up to 30 min. in 20°C)

- For use in positive temperatures

- Diamond and hammer drilling

Applications:

- Safety barriers

- Formwork support systems

- Structural steelwork

- Street lamps

- Curtain walling

- Racking systems

- Balustrading

- Barriers

- Cladding restraints

- Masonry support

- Heavy machinery

- Platforms

Installation Guide:

- Drill hole to the required diameter and depth for stud size being used.

- Clean the hole thoroughly with brush and hand pump at least four times before installation.

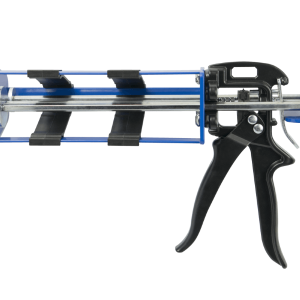

- Insert cartridge into gun and attach nozzle.

- Dispense to waste until even colour is obtained.

- Insert the mixer nozzle to the bottom of the drill hole and inject resin, slowly withdrawing the nozzle as the hole is filled to 70% of its depth.

- Immediately insert the stud, slowly and with slight twisting motion.

- Remove any excess resin around the hole before it sets and leave it undisturbed until the curing time elapses.

- Attach fixture and tighten the nut to the required torque.

Reviews

There are no reviews yet.