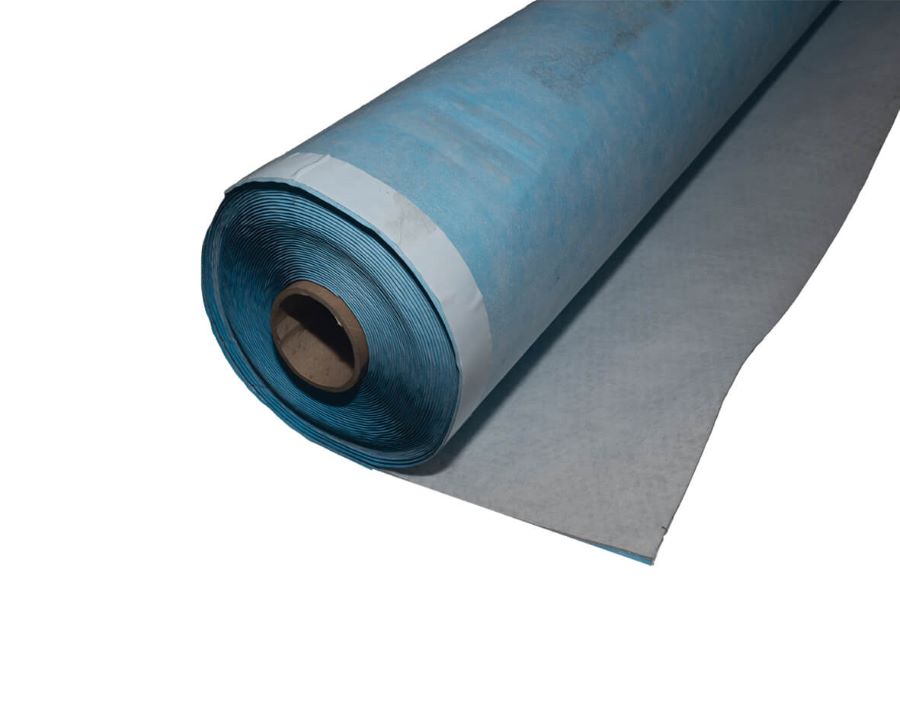

Waterproofing Membrane and Gas Barrier. Newton HydroBond 403 is a high performance, self-healing membrane with a locking fleece on the inner surface and a hydrophilic polymer coating externally. The membrane is BDA approved, NHBC accepted as Type A waterproofing, and the gas barrier variant provides resistance to radon, carbon dioxide and hydrocarbons.

HydroBond 403 provides a complete waterproof envelope to the structure to achieve Type A (barrier) waterproofing suitable for Grades 1, 2 and 3 as defined by BS 8102:2022, is suitable for all below ground and earth-retained structures from domestic basements to the largest civil engineering projects, and can be used as part of the HydroBond® System with HydroBond 108-LM which is sprayed to the exposed walls of the basement after the temporary formwork is removed. Where space is tight, HydroBond 109-LM can be applied by roller or brush or small airless spray machine.

HydroBond 403 can be used in conjunction with other Newton products to provide a coordinated and combined approach to the waterproofing of the whole structure that includes protection against water ingress to the deck, through construction joints, through and around service entries and to movement joints.

Correctly protected, the Newton HydroBond System will provide, under normal service conditions, a durable waterproof barrier for the life of the building to which it is installed; the expected lifetime of the building itself should be at least 60 years. The Newton HydroBond System is supported by BDA Agrément Certificate BAB 16-031/03/A and is accepted by the NHBC as a suitable waterproofing system for Type A Waterproofing to Grades 1, 2 & 3 – BS 8102:2022

Key Benefits

- Agrément certified and NHBC accepted waterproofing system.

- Forms a full mechanical bond to concrete to prevent water migration between the membrane and the structure.

- The hydrophilic layer provides self-healing capabilities when the membrane is punctured.

- Very flexible – resistant to movement and fissures in substrates.

- Excellent resistance to the high alkalinity of concrete.

- Third-party test certification for radon, carbon dioxide and hydrocarbon gases.

- The Newton HydroBond™ System completely encapsulates the structure.

Typical Applications

- As a continuous membrane to permanent raft and wall formwork such as the raft blinding and piled walls of reinforced concrete and earth-retained structures.

Suitable Substrates:

RAFT OR SLAB

- Concrete blinding.

- Compacted type 1 hardcore.

- Compacted sand.

The following can be placed above the blinding or hardcore prior to the installation of HydroBond 403:

- Void former.

- Clay heave board.

- Closed-cell flooring grade insulation.

- HydroBond 410 GeoDrain.

WALL FORMWORK

- Existing structure.

- Secant or contiguous concrete piles.

- Metal sheet piles.

- Diaphragm walls.

- King post wall.

- Sufficiently stable ground such as clay or chalk.

- Temporary timber shuttering/formwork.

Reviews

There are no reviews yet.