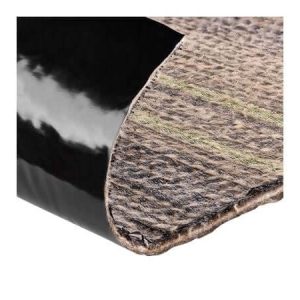

Bentonite geotextile waterproofing system. VOLTEX® is a highly effective waterproofing composite of high strength geotextiles and 4.8 kg/sqm of sodium bentonite. The high swelling, low permeable sodium bentonite is encapsulated between a non-woven and woven geotextile. A proprietary needle punch process interlocks the geotextiles together forming an extremely strong composite that maintains the equal coverage of bentonite, as well as protects it from inclement weather and construction related damage.

Once backfilled, VOLTEX® hydrates and forms a monolithic waterproofing membrane. VOLTEX® contains zero VOC, can be installed in almost any weather condition to green concrete, and most importantly, has proven effective on both new and remedial waterproofing projects worldwide.

VOLTEX® works by forming a low permeability membrane upon contact with water. When wetted, unconfined bentonite can swell up to 15 times its dry volume. When confined under pressure the swell is controlled, forming a dense, impervious waterproofing membrane.

The swelling action of VOLTEX® can self-seal small concrete cracks caused by ground settlement, concrete shrinkage, or seismic action; problems over which there is normally no control. VOLTEX® forms a strong mechanical bond to concrete when the geotextile fibres are encapsulated into the surface of cast-in-place concrete.

Applications:

VOLTEX® is d esigned for below-ground vertical and horizontal structural foundationsurfaces. Typical cast-in-place concrete applications include backfilled concrete walls, earth-covered roofs, structural slabs, tunnels, and property line construction. Property line construction applications include soldier pile and lagging, secant/contiguous piling, steel sheet piling, shotcrete and stabilized earth retention walls. Applications may include structures under continuous or intermittent hydrostatic pressure.

Limitations:

VOLTEX® should only be installed after substrate preparation has been properly completed and is suitable to receive the waterproofing system. Concrete work should be cast-in-place with conventional forms that produce a smooth surface. VOLTEX® is d esigned for below-ground waterproofing applications where the product is properly confined. VOLTEX® should not be installed in standing water or over ice. If ground water contains strong acids, alkalis, or is of a conductivity of 2500 ?mhos/cm or greater, water samples should be submitted to the manufacturer for compatibility testing. ULTRASEAL XP may be required if contaminated ground water or saltwater conditions exist.

VOLTEX® is designed for use under reinforced concrete slabs 100 mm thick or greater on a compacted earth/gravel substrate. VOLTEX® requires a minimum 150 mm thick reinforced concrete slab if installed over a concrete blinding. VOLTEX® is not designed for split-slab plaza deck construction.

VOLTEX® is not intended to seal expansion joints; contact CETCO for expansion joint applications. Do not use VOLTEX® on masonry block foundation walls. Consult CETCO for special installation guidelines that apply to shotcrete and precast concrete construction.

VOLTEX® installation guidelines are for cast-in-place concrete applications and do not cover shotcrete or precast concrete applications. Refer to VOLTEX® Product Manuals for additional property line shoring wall construction technique applications. Consult CETCO for applicable products and installation guidelines for applications not covered herein.

Size and Packaging:

VOLTEX® is available in 1.1 x 5m rolls. Typical roll weight is approximately 33 kg. VOLTEX® is packaged 35 rolls per pallet (192.5 sqm).

Reviews

There are no reviews yet.