Structural waterproofing products in construction encompass a broad range of materials and systems designed to prevent the ingress of water into building structures and below-ground spaces. These products are vital for protecting foundations, basements, and below-grade structures from water damage, dampness, and deterioration. The classification of waterproofing systems into Type A, Type B, and Type C is outlined in British Standard 8102:2022, which provides guidance on waterproofing design and installation practices.

Type A Waterproofing Systems

Type A waterproofing systems, also known as barrier waterproofing systems, involve the application of waterproof membranes or coatings to either the external or internal surface of the structure. These membranes create a barrier that prevents the passage of water into the building envelope.

Examples of Type A waterproofing systems include sheet membranes, liquid-applied membranes, cementitious coatings, and bituminous coatings. These materials are applied directly to the exterior or interior surfaces of below-ground structures, such as basements and substructures.

Installation of Type A waterproofing systems typically involves surface preparation, application of the waterproofing membrane or coating, and detailing around penetrations, joints, and transitions. Proper installation is critical to ensure continuity and integrity of the waterproofing barrier.

Type B Waterproofing Systems

Type B waterproofing systems, also known as structural integral waterproofing systems, involves ensuring that the concrete structure itself acts as a barrier to water. This is achieved by ensuring that penetrations and gaps in the concrete, such as construction joints and service entries, are sealed, and sometimes by also incorporating waterproofing additives or admixtures into the concrete used in the construction of the structure. These additives enhance the properties of the concrete itself.

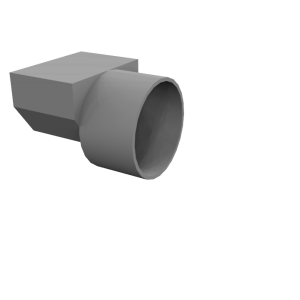

Examples of Type B waterproofing products include waterbars, injection resin systems, and joint sealing systems, and may also include crystalline admixtures, hydrophobic admixtures, and polymer-modified additives. These materials are mixed with the concrete or mortar during the batching process.

Installation of Type B waterproofing systems is integrated into the construction process. Proper concrete placement, curing, and protection practices are also essential to ensure the effectiveness of the waterproofing.

Type C Waterproofing Systems

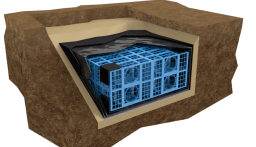

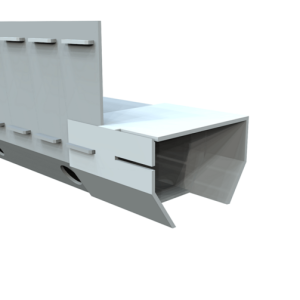

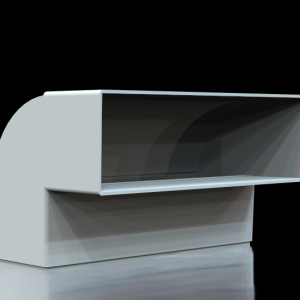

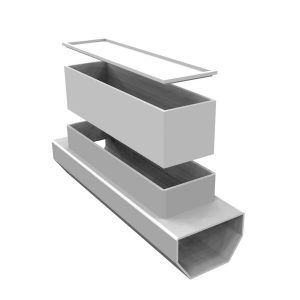

Type C waterproofing systems, also known as drained cavity systems or cavity drain systems, involve the installation of internal cavity membranes and drainage channels to manage and control water ingress within the structure. These systems collect and redirect water to sumps or drainage points for removal.

Installation of Type C waterproofing systems involves fixing drainage membranes or channels to the internal surfaces of the structure, creating a cavity or void space behind the membrane for water collection. Other products in Type C waterproofing systems include drainage channels, sump pump systems, and backup and control devices.

The Importance of Proper Waterproofing Systems

Structural waterproofing products play a crucial role in protecting buildings and below-ground structures from water damage, dampness, and deterioration. By implementing effective waterproofing measures, construction professionals can ensure the long-term integrity and durability of buildings, safeguarding against costly repairs and structural failures.

When selecting structural waterproofing products for a construction project, factors such as site conditions, building usage, groundwater levels, and local regulations should be considered. It's essential to consult with waterproofing specialists and adhere to industry standards and best practices to ensure the proper design, installation, and maintenance of waterproofing systems. Additionally, periodic inspections and maintenance are essential to monitor the performance and integrity of waterproofing systems over time.

What Structural Waterproofing brands do we stock?

We stock and supply a choice of sealants, adhesives and primers from a choice of brands, with options covering different application scenarios and product requirements. This includes products from

Cetco,

Diasen,

Filoform,

FIXA,

Hauff-Technik,

Newton Waterproofing Systems,

RiveStop and

Visqueen.