Type A waterproofing products, specifically external waterproofing membranes, are a category of construction materials designed to provide waterproofing protection to the external surfaces of below-ground structures, such as basements, foundations, retaining walls, and below-ground concrete slabs. These membranes create a continuous and impermeable barrier that prevents water ingress and protects the structure from moisture-related damage. The category includes both liquid-applied and sheet membranes.

Liquid-Applied Waterproofing Membranes

Liquid-applied external membranes are viscous liquid formulations applied directly onto the surface of concrete, masonry, or other substrates using spray, brush, or roller methods. These membranes cure to form a seamless and often flexible waterproof barrier that adheres tightly to the substrate.

Sheet Waterproofing Membranes

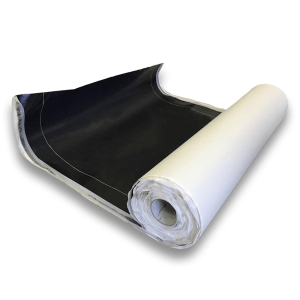

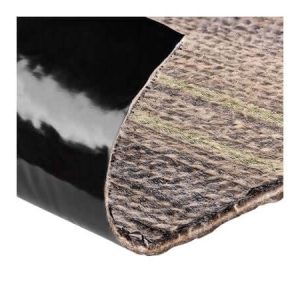

Sheet membranes are prefabricated waterproofing membranes made from bitumen, PVC, EPDM, TPO, or other synthetic materials. These membranes are typically supplied in rolls or sheets and are either pre-applied to the site or formwork, or post-applied to the substrate using adhesives, heat welding, or mechanical fastening methods. Sheet membranes provide a durable and puncture-resistant waterproofing layer that withstands environmental exposure.

Characteristics of External Waterproofing Membranes

Waterproofing Properties: External membranes provide excellent waterproofing protection by forming a continuous barrier that prevents water penetration. They resist hydrostatic pressure and effectively protect against groundwater.

Flexibility: Many external membranes are flexible or elastomeric, allowing them to accommodate substrate movement and structural settlement without compromising the waterproofing.

Durability: External membranes are durable and resistant to weathering, UV exposure, and chemical attack. They provide long-lasting protection against moisture-related damage and deterioration of the structure.

Adhesion: Liquid-applied membranes adhere tightly to the substrate, providing excellent bond strength and adhesion. Sheet membranes utilise adhesives or mechanical bonds to ensure a secure attachment to the substrate.

Ease of Application: Liquid-applied membranes are applied using standard techniques including spray, brush, and roller. Sheet membranes are generally straightforward to apply, but both types of external membrane require proper surface preparation.

Sheet Waterproofing Membrane Applications & Considerations

External membranes are used in various construction applications, including: Waterproofing of below-grade concrete foundations and basements; Protection of retaining walls, elevator pits, and planters; Waterproofing of podium decks, plaza decks, and green roofs; and Sealing of below-ground tunnels, parking garages, and infrastructure projects

When installing external waterproofing membranes, it is also important to consider some important factors:

Proper surface preparation is essential for adhesion and waterproofing performance.

Installation techniques and compatibility with other construction materials should be considered.

Careful handling and proper detailing, especially of sheet membranes, to ensure watertight seams and transitions.

Liquid-applied membranes may require

multiple coats and curing time before backfilling or exposing to traffic.

Contact BaseTec - Complete Systems. Reliably Delivered.

If you require assistance with external waterproofing membranes or need advice on which product is best suited for your requirements, contact our friendly teams in Kent - 01732 906 826 - or Leeds - 0113 521 6789.

Return to our full range of

Structural Waterproofing products.