What Are Chemical Anchor Resins?

Chemical anchor resins, also known as chemical anchoring adhesives or chemical anchor systems, are used to securely bond and anchor various fixtures, structural elements, and components to concrete, masonry, stone, and other substrates. The resins typically consist of two main components: a resin and a hardener. When mixed together, these components undergo a chemical reaction, resulting in a strong, durable bond capable of withstanding large loads and forces.

Chemical Anchor Resin Uses

Anchor resins are used for a wide range of anchoring and fixing applications in construction, including:

Anchoring Bolts and Dowels: Commonly used to anchor bolts, threaded rods, reinforcement bars (rebar), and dowels into concrete and masonry substrates. These anchored elements provide structural support and stability for various components, such as columns, beams, walls, and machinery.

Fixing Structural Components: Used to fix structural components, such as steel plates, brackets, angles, and channels, to concrete and masonry surfaces. This allows for secure attachment and load transfer between structural elements, enhancing the overall stability and performance of the structure.

Attaching Facade Elements: Employed to attach facade elements, such as cladding panels, curtain wall brackets, and facade support systems, to building exteriors. This ensures secure installation and resistance to wind, seismic, and other external loads.

Handrails and Guardrails: Utilised for installing handrails, guardrails, safety barriers, and balustrades on staircases, walkways, balconies, and elevated platforms.

Reasons for Using Chemical Anchor Resins

There are several reasons why chemical anchor resins are preferred for anchoring and fixing applications:

High Load Capacity: Chemical anchor resins provide high load-bearing capacity and shear strength, allowing for reliable anchoring of heavy loads and structural elements.

Fast Curing: Many anchor resins offer rapid curing times, allowing for quick installation and minimal downtime in construction projects.

Versatility: Can be used with a variety of substrates, including concrete, masonry, brick, stone, and some metals, making them suitable for diverse applications in construction.

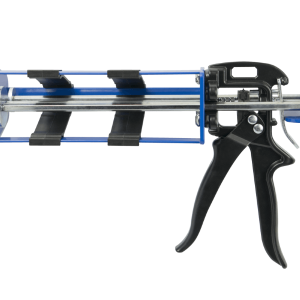

Ease of Installation: Chemical anchor systems are easy to install and require minimal equipment, making them suitable for both professional contractors and DIY enthusiasts.

Durability: Chemical anchor resins provide durable, long-lasting bonds that resist environmental factors such as moisture, temperature fluctuations, and chemical exposure.

Aesthetic Considerations: Chemical anchor resins offer a concealed fixing solution, eliminating the need for visible fasteners and preserving the aesthetic appearance of architectural elements and surfaces.

Contact BaseTec - Complete Systems. Reliably Delivered.

If you require assistance with chemical anchor resins or need advice on which anchor resin product is best suited for your requirements, contact our friendly teams in Kent - 01732 906 826 - or Leeds - 0113 521 6789.

Return to our full range of

Grouts and Chemical Anchors.