Cementitious grouts and chemical anchors encompass a range of materials for anchoring, fixing, and repairing various components and structural elements in construction projects. These products play a critical role in ensuring the stability, durability, and safety of buildings, infrastructure, and other structures.

Cementitious Grouts

Cementitious grouts are versatile construction materials composed of cement, aggregates, additives, and water. They are commonly used for filling voids, cracks, and gaps in concrete structures, anchoring bolts and reinforcement bars, underpinning foundations, sealing joints, and repairing damaged or deteriorated concrete. Cementitious grouts offer high strength, durability, and versatility, making them suitable for a wide range of applications in construction.

Chemical Anchors

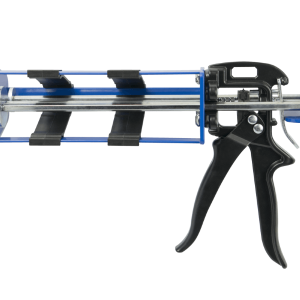

Chemical anchors, also known as chemical anchor resins or adhesive anchors, are adhesives used to securely bond and anchor fixtures, structural elements, and components to concrete, masonry, stone, and other substrates. These adhesives typically consist of two components: a resin (adhesive) and a hardener (curing agent), which react chemically to form a strong, durable bond. Chemical anchors are widely used for anchoring bolts, dowels, reinforcement bars, fixing structural components, attaching facade elements, and installing handrails and guardrails.

Cementitious Grouts and Chemical Anchor Applications

Cementitious grouts and chemical anchors are essential construction products that provide reliable solutions for various anchoring, fixing, and repair applications in the built environment. They are used in residential, commercial, industrial, and infrastructure projects to enhance structural stability, ensure safety, and prolong the service life of buildings and structures. These products offer high performance, ease of installation, durability, and compatibility with different substrates, making them indispensable in modern construction.

Key Considerations for Grouts and Chemical Anchors

When selecting cementitious grouts and chemical anchors for a specific project, several factors should be considered, including substrate conditions, load requirements, environmental factors, curing time, application method, and compliance with relevant standards and regulations. It's essential to consult with suppliers, manufacturers, or construction professionals to choose the most suitable products and ensure proper installation and performance.

What cementitious grout and chemical anchor product brands do we stock?

We stock and supply a choice of cementitious grouts and chemical anchors from some of the leading UK construction brands for these product types. This includes products from

Rawlplug and

Tarmac.