Flat roof waterproofing is essential to prevent water infiltration, which can lead to structural damage and other significant issues.

How is Flat Roof Waterproofing Applied?

Inspect the Roof: Before starting any waterproofing work, thoroughly inspect the roof for existing damage, cracks, or areas of deterioration. Address any repairs needed before proceeding.

Clean the Surface: Remove any debris, dirt, and vegetation from the roof surface. Clean the roof thoroughly to ensure a good application of your waterproofing material.

Repair Cracks and Damage: Patch any cracks, holes, or damaged areas in the roof substrate using appropriate repair materials.

Choose Flat Roof Waterproofing Materials: Select the appropriate waterproofing materials based on your roof type, budget, and performance requirements. Common options include liquid-applied membranes, bitumen-based coatings, single-ply membranes (such as EPDM or TPO), or waterproofing membranes with reinforcement.

Apply Primer: Apply a primer to the roof surface to enhance adhesion and ensure proper bonding of the waterproofing membrane or coating. Follow manufacturer instructions for primer application and drying time.

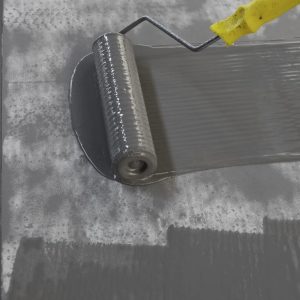

Apply Flat Roof Waterproofing System: If recommended by the manufacturer, apply a primer to enhance adhesion and ensure proper bonding of the waterproofing. Apply the chosen waterproofing material according to manufacturer guidelines.

Seal Joints and Penetrations: Pay special attention to roof joints, seams, edges, and penetrations such as vents, pipes, and HVAC units. Use appropriate materials to seal these areas and prevent water infiltration.

Install Drainage Systems: Ensure proper drainage on the flat roof to prevent standing water, which can accelerate roof deterioration. Install or maintain roof drains, gutters, and downspouts to channel water away from the roof surface.

Inspect and Maintain Regularly: Post-completion, conduct regular inspections and maintenance to identify any issues early and address them promptly. Clean debris from gutters and drains regularly to prevent clogs and standing water.

By following these steps and ensuring proper installation of waterproofing materials, you can effectively protect your flat roof from water damage and extend its lifespan.

What flat roof waterproofing brands do we stock?

We stock and supply a choice of liquid-applied flat roof waterproofing membranes, including flexible and single-component waterproofing membranes that can be applied to damp substrates and even in cold temperatures. This includes products from

FIXA and

Winkler.