Bonding Agents & Admixtures

Brand

Type

Pump Type

Pump Size

Inverter Size

Battery Size

Number of Pumps

Discharge Points

Width

Length

Area

Size

Material

Components

Features

Pack size

Suitable for

Color

Thickness

Maximum Repair Depth

Application Area

Variants

Depth

Density

Range

Showing all 12 results

-

Adomast Adoflow ACF Concrete Accelerator & Plasticiser – 25 Litre

£82.90 incl. VAT£69.08 excl. VAT -

Adomast Adoflow ACF Concrete Accelerator & Plasticiser – 5 Litre

£19.43 incl. VAT£16.19 excl. VAT -

Adomast Adoflow Extra PCE High Efficiency Superplasticiser – 20 Litre

£78.89 incl. VAT£65.74 excl. VAT -

Adomast Adoflow Extra PCE High Efficiency Superplasticiser – 25 Litre

£96.29 incl. VAT£80.24 excl. VAT -

Adomast Adoflow Extra Super Plasticiser for Concrete – 25 Litre

£67.97 incl. VAT£56.64 excl. VAT -

Adomast Adoflow Extra Superplasticiser for Concrete – 5 Litre

£19.62 incl. VAT£16.35 excl. VAT -

Adomast Adoprufe Integral Concrete Waterproofing – 25 Litre

£88.30 incl. VAT£73.58 excl. VAT -

Adomast Adoprufe Integral Concrete Waterproofing – 5 Litre

£17.94 incl. VAT£14.95 excl. VAT -

Visqueen IGW Admix – 6 Bags in 1 Container

£473.09 incl. VAT£394.24 excl. VAT -

Newton HydroCoat LiquaBond – 5 Litre

£62.22 incl. VAT£51.85 excl. VAT -

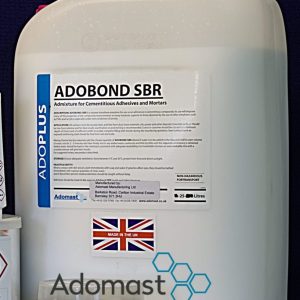

Adomast Adobond SBR Bonding Adhesive – 5 Litre

£30.10 incl. VAT£25.08 excl. VAT -

Adomast Adobond SBR Bonding Adhesive – 25 Litre

£112.42 incl. VAT£93.68 excl. VAT

Showing all 12 results